The West Trunk Sewer Project Contract 2 stands as a testament to innovation and efficiency – one remarkable feature that has contributed significantly to the project’s success is the use of compressible grout. Compressible grout is a revolutionary material that has been making waves in underground construction, particularly in projects like West Trunk Sewer Project Contract 2.

This article explores the advantages of this unique material and its application in Contract 2 where Technicore Canada played a pivotal role, providing insights into how it has revolutionized the construction of a 3.8 km-long tunnel with a minimum internal diameter of 2.4m, a mid-tunnel drop shaft, and challenging geological conditions. From providing stability to minimizing water leakage and gas penetration, compressible grout has proven to be a game-changer in tunnelling projects.

The Unique Composition of Compressible Grout

Compressible grout’s effectiveness lies in its innovative and unique design. It is a patented blend of cement, bentonite, foam particles, and admixtures. This composition results in a material that, when hardened, can withstand the expected time-dependent deformation of rock, making it an ideal choice for tunnelling projects with challenging geological conditions.

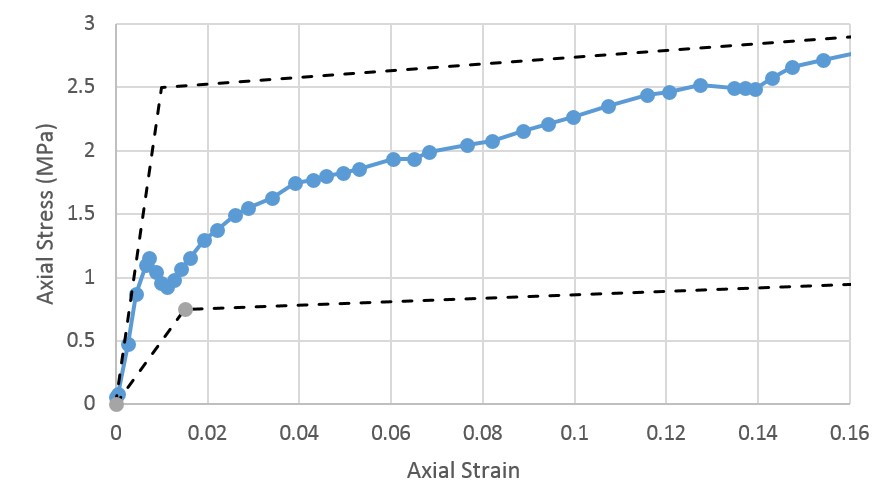

To understand why compressible grout is so effective, it’s crucial to look at its material characteristics. Tests were conducted using steel cylinders to measure lateral confinement and confined compression strength. These tests were performed under controlled conditions, providing valuable insights into the material’s properties. The results reveal a material capable of accommodating significant deformation while maintaining its structural integrity.

Innovations on West Trunk Sewer Contract 2

In West Trunk Sewer Project Contract 2, compressible grout played a vital role in overcoming the project’s unique challenges. With a 3.8km tunnel, varying geological layers, and stringent requirements for stability and corrosion resistance, this project required innovative solutions. Compressible grout rose to the occasion, meeting the project’s demands and ensuring its success.

Enhancing Stability and Performance with Compressible Grout

In the construction of underground tunnels, ensuring the stability of the surrounding soil or rock is paramount. This is where compressible grout shines. It offers several advantages that make it an ideal choice for projects like the West Trunk Sewer Project Contract 2:

Accommodating Deformation

One of the standout features of compressible grout is its ability to accommodate deformation. In the context of tunnelling, deformation refers to the changes in the shape and size of the annular space surrounding the tunnel lining. Compressible grout can handle deformation of up to 16%, and this percentage can be adjusted by altering the mix design. This flexibility is invaluable in scenarios where the surrounding geological conditions are prone to shifts and changes.

Minimizing Overstress

Overstressing the tunnel lining can lead to structural issues and potentially catastrophic failures. Compressible grout acts as a safeguard against such overstress. It helps distribute forces evenly and prevents undue pressure on the tunnel lining. This ensures the long-term structural integrity of the tunnel, even in the face of geological movements.

Water and Gas Leakage Prevention

Water infiltration into tunnels can be a major problem, causing damage and affecting the overall functionality of the structure. Compressible grout, when used as a backup to the gasket, helps minimize water leakage. Additionally, it serves as a barrier to the penetration of gases like methane, which can be hazardous in tunnel environments. This dual functionality enhances safety and reliability in tunnel projects.

The Unique Composition of Compressible Grout

Compressible grout’s effectiveness can be attributed to its innovative composition. It is a proprietary blend that combines various elements to create a material with exceptional properties:

- Cement: The cement component provides the necessary strength and binding properties to the grout. It ensures that the material can withstand the pressures and stresses encountered in tunnelling.

- Bentonite: Bentonite, a clay-like material, adds plasticity and helps maintain the material’s consistency. It also contributes to the grout’s ability to seal against water and gas infiltration.

- Foam Particles: The inclusion of foam particles is a key feature. These particles create voids within the grout, making it compressible while still retaining its structural integrity. This unique characteristic allows the grout to adapt to deformation.

- Admixtures: Various admixtures are incorporated to fine-tune the properties of the grout, ensuring it meets the specific requirements of each project.

This carefully balanced combination results in a material that is not only strong but also flexible, making it well-suited for tunnel construction in varying geological conditions.

Material Characteristics and Testing Methodology

Understanding the material characteristics of compressible grout is crucial for ensuring its performance in demanding tunnelling projects. Rigorous testing by Technicore was conducted to evaluate its properties, including lateral confinement and confined compression strength. Tests involved the use of steel cylinders to simulate the conditions in which the grout would be used. These tests were performed under controlled conditions, including specific rates of axial deformation. The results provided valuable data, including:

- Young’s Modulus: This parameter measures the material’s elasticity and ability to return to its original shape after deformation. Compressible grout demonstrated favourable Young’s Modulus values, indicating its ability to recover from deformation.

- Peak Compressive Strength: This is a critical parameter, as it indicates the maximum pressure the grout can withstand before failing. Compressible grout exhibited impressive peak compressive strength, ensuring its structural stability.

The testing process also involved allowing the grout to undergo significant axial deformation before completion, simulating real-world scenarios where the material needs to adapt to deformation without compromising its integrity.

These tests confirmed that compressible grout possesses the necessary characteristics to excel in challenging tunnelling projects like West Trunk Sewer Project Contract 2.

Innovations on West Trunk Sewer Contract 2

The West Trunk Sewer Project Contract 2 presented several unique challenges that demanded innovative solutions. Let’s explore how compressible grout played a pivotal role in this project’s success.

Project Description

- The West Trunk Sewer Project Contract 2 was a substantial undertaking with the following key features:

A 3.8km (12,500ft) long tunnel. - A minimum internal diameter of 2.4m (8ft).

- A mid-tunnel drop shaft with a depth of 28m.

- Geological conditions consist of interbedded cohesive and granular layers, overlying Georgian Bay Shale.

Compressible Grout – Requirements

The project’s requirements were stringent, necessitating a solution that could provide stability, accommodate deformation, prevent overstressing of the lining, and minimize water and gas infiltration. Compressible grout proved to be the ideal choice, meeting all these requirements effectively.

Integrated Corrosion Resistant Lining

Another unique aspect of this project was the need for a corrosion-resistant lining. The client specified the use of AGRUSAFE SureGrip® HDPE lining with a minimum thickness of 5mm. This lining was required for a specific section of the tunnel, encompassing 150m upstream and 100m downstream of the drop shaft. Also, Herrenknecht Combisegments® were used for this 250m length, providing a reliable and durable lining solution.

Conclusion

Compressible grout has emerged as a revolutionary material in the realm of tunnel construction, and its advantages were vividly demonstrated in the West Trunk Sewer Project Contract 2. Its ability to provide stability, accommodate deformation, prevent overstressing, and act as a barrier against water and gas infiltration makes it a valuable asset in challenging tunnelling projects.

With its unique composition and favourable material characteristics, compressible grout is set to continue transforming the way we approach underground construction. In the ever-evolving field of civil engineering, innovations like compressible grout are essential for building a safer and more resilient infrastructure.

Процесс создания аккаунта в казино 7k 7к casino официальный сайт максимально упрощен и не требует много времени. Новым пользователям нужно указать базовую информацию, и уже через минуту приступить к игре. Приятным дополнением является наличие приветственных бонусов, что помогает увеличить стартовый баланс. Легкость регистрации и выбор игр делают платформу 7k удобной как для новых, так и для опытных игроков.

A round of applause for your article post.Thanks Again. Keep writing.

I needed to thank you for this good read!! I absolutely enjoyed every bit of it. I have got you bookmarked to check out new things you post…

Hey, you used to write wonderful, but the last few posts have been kinda boring… I miss your super writings. Past few posts are just a little out of track! come on!

Hi there, just became aware of your blog through Google,and found that it’s truly informative. I’m going to watch out for brussels.I will be grateful if you continue this in future. Many people will be benefited from your writing.Cheers!

Thanks again for the blog article.Much thanks again. Want more.

A big thank you for your blog post.Much thanks again. Awesome.

Really enjoyed this article. Really Cool.

Major thanks for the blog article.Really looking forward to read more. Want more.

Enjoyed every bit of your blog.Really looking forward to read more. Great.

I am so grateful for your post.Much thanks again. Great.

Say, you got a nice article post.Really thank you! Awesome.

Wow, great blog article.Much thanks again. Really Cool.

Thanks-a-mundo for the blog.Thanks Again. Fantastic.

The Boys: Winter 3 tiene mucho coloquialismo que los niños

Hi, I read your new stuff like every week. Your humoristicstyle is witty, keep doing what you’re doing!

Whats Happening i am new to this, I stumbled upon this I have discovered It positively helpful and it has aided me out loads. I hope to give a contribution & aid different users like its aided me. Good job.

I like what you guys tend to be up too. This sort of clever work and coverage!Keep up the wonderful works guys I’ve you guys to my blogroll.

Thank you for the auspicious writeup. It if truth betold used to be a leisure account it. Glance complex to far brought agreeablefrom you! However, how can we keep up a correspondence?

Very neat post.Thanks Again. Cool.

It is really a great and useful piece of information. I’m happy that you shared this helpful information with us.Please keep us informed like this. Thanks for sharing.

wow, awesome blog article.Thanks Again. Awesome.

Major thankies for the article. Much obliged.

Good replies in return of this issue with solid arguments and explaining everything concerning that.

I join. It happens. We can communicate on this theme.

Hello friends, how is everything, and what you wish for tosay concerning this article, in my view its in factawesome in support of me.

You could definitely see your skills in the work you write. The world hopes for even more passionate writers like you who aren’t afraid to say how they believe. Always go after your heart.

Great post. I was checking continuously this blog and I’m impressed!Extremely useful info specially the last part 🙂 I care for such information much. I was seeking this certain info for a very longtime. Thank you and good luck.

Hello! I just would like to offer you a big thumbs up for your great info you’ve got here on this post. I am returning to your blog for more soon.

639334 909565Which is some inspirational stuff. Never knew that opinions may well be this varied. Thank you for all of the enthusiasm to supply such beneficial information here. 949859

This is one awesome blog article.Much thanks again. Really Cool.

Really appreciate you sharing this blog.Much thanks again. Want more.

Thanks a lot for the post.Really looking forward to read more. Much obliged.

Hemen tıkla: Youtube İzlenme Süresi Arttırma Hilesi

Exceptional post however , I was wondering if you could writea litte more on this subject? I’d be very thankful if you could elaborate a littlebit more. Many thanks! 外贸 是 什么 导航

Thanks for finally talking about > Dosen Terbaik II Semester Ganjil Tahun 2018/2019

Outstanding story there. What occurred after?Thanks!

I’m really inspired along with your writing abilities and alsowith the format for your blog. Is this a paid theme or did you modify it yourself?Anyway keep up the nice quality writing, it is uncommon to see a nice blog like this one these days..

Thanks-a-mundo for the post. Great.

I really like and appreciate your blog article.Much thanks again. Really Great.

Heya i’m for the primary time here. I found this board and I to find It really useful & it helped me out a lot. I’m hoping to give one thing back and help others like you aided me.

Very neat blog.Really looking forward to read more. Really Cool.

Great blog.Thanks Again. Much obliged.

Thanks-a-mundo for the post.Really thank you! Really Cool.

I really enjoy the post.Thanks Again. Fantastic.

Thanks for sharing, this is a fantastic article post.Thanks Again. Really Great.

I want to to thank you for this very good read!! I definitely loved every little bit of it. I have you saved as a favorite to check out new stuff you postÖ

Enjoyed every bit of your blog article.Really looking forward to read more. Keep writing.

Wow, great blog post.Really thank you! Really Great.

I really liked your article.Thanks Again. Fantastic.

aranżacja wnętrz Gdynia[…]Wonderful story, reckoned we could combine several unrelated information, nonetheless seriously worth taking a appear, whoa did 1 study about Mid East has got more problerms too […]

Thanks again for the blog.Really looking forward to read more. Really Cool.

This is one awesome article.Thanks Again. Awesome.

I truly appreciate this post.

Say, you got a nice post.Much thanks again. Much obliged.

Cómo agregar mapa de organización y esquema a YouTube Docs o skid

Hey, thanks for the blog.Really thank you! Will read on…

Major thankies for the post.Really looking forward to read more. Awesome.

Hey, thanks for the article post.Thanks Again. Great.

Hey, thanks for the article.Really looking forward to read more. Much obliged.

Thanks for sharing, this is a fantastic article.Thanks Again. Awesome.

Thanks so much for the blog.Really thank you! Really Cool.

Major thankies for the post.Thanks Again. Keep writing.

Thank you ever so for you blog article.Really thank you!

write college essays essay on technology write my essays

Helpful info. Lucky me I found your web site accidentally, and I’m shocked why this twist of

fate didn’t happened earlier! I bookmarked it.

Thanks-a-mundo for the article post.Thanks Again. Want more.

I do consider all the ideas you have offered for your post. They are very convincing and will certainly work. Still, the posts are very short for beginners. Could you please prolong them a bit from subsequent time? Thanks for the post.

chloroquine hydrochloride hydroxychloroquine for covid

Thanks so much for the blog. Want more.

Your style is unique in comparison to other people

I’ve read stuff from. Thank you for posting when you have the

opportunity, Guess I will just bookmark this web site.

online pharmacy reviews – canadian pharmacy rx reputable canadian online pharmacy

I really like and appreciate your blog post.Really looking forward to read more. Will read on…

I do agree with all of the ideas you have presented in your post. They’re really convincing and will definitely work. Still, the posts are too short for beginners. Could you please extend them a bit from next time? Thanks for the post.

With havin so much content do you ever run into any issues

of plagorism or copyright violation? My site has a lot

of unique content I’ve either written myself or outsourced but it seems a lot

of it is popping it up all over the web without my authorization. Do

you know any ways to help stop content from being ripped off?

I’d certainly appreciate it.

Super Sweet Crush says:There’s definately a great deal to learn about this issue. I like all of the points you’ve made.Reply 05/27/2020 at 11:40 pm

I always spent my half an hour to read this website’s articles all the

time along with a mug of coffee.

Everyone loves what you guys are usually up too. This sort of clever work and exposure! Keep up the fantastic works guys I’ve included you guys to my own blogroll.

Good blog you’ve got here.. It’s hard to find high quality writing like yours these days. I honestly appreciate people like you! Take care!!

I truly appreciate this blog article. Awesome.

Awesome blog.Really thank you! Fantastic.

Im obliged for the blog. Much obliged.

I truly appreciate this blog article.Really thank you! Fantastic.

Great blog.Really thank you! Great.

Looking forward to reading more. Great blog article.Really looking forward to read more. Awesome.

Say, you got a nice blog.Really thank you!

I truly appreciate this blog.Really thank you! Keep writing.

Your style is really unique in comparison to other people I have

read stuff from. Thank you for posting when you’ve

got the opportunity, Guess I’ll just bookmark this

web site.

Simply a smiling visitant here to share the love (:, btw outstanding style .

A highly requested article, we’ll teach you how to find a replica Balenciaga Handbags dealer you can actually trust.

Thanks again for the blog article.Really looking forward to read more. Awesome.

I really like and appreciate your post.Thanks Again. Will read on…

azithromycin pneumococcus — over the counter meds similar to a zpack zithromax z-pak dosage

I think this is a real great post.Really looking forward to read more.

Wow, great blog article.Thanks Again. Will read on…

Thanks for sharing, this is a fantastic article.Thanks Again. Much obliged.

Tienda Nº 1 en Chandal BarcelonaEncontrarás cada chandal del barça 2022 y ropa deentrenamiento de los clubs y selecciones nacionales para adultos y niños.

Wow, great blog article.Really thank you!

I do consider all the ideas you’ve presented for your post.They are very convincing and will definitely work. Nonetheless, the postsare very quick for beginners. Could you please lengthen them alittle from next time? Thanks for the post.

What’s up, I would like to subscribe for this blog to obtain most recent updates, so where can i do it please assist.

A round of applause for your article.Really looking forward to read more. Will read on…

It’s a great sharing of your content, my friend…

That is a very good tip particularly to those fresh tothe blogosphere. Simple but very accurate info… Thanks for sharing this one.A must read article!

Fantastic blog.Really looking forward to read more. Really Cool.

ivermectin 3 ivermectin – generic ivermectin for humansivermectin cream 5

There’s definately a lot to find out about this subject. I love all of the points you’ve made.

What’s up friends, how is everything, and what you wish for tosay concerning this piece of writing, in my view its truly awesomedesigned for me.

I do not even know how I ended up here,but I thought this post was good. I don’t know who you are butdefinitely you are going to a famous blogger if you aren’talready 😉 Cheers!

Very neat article post.Really looking forward to read more. Keep writing.

Fantastic article post.Thanks Again. Keep writing.

Major thanks for the article. Fantastic.

hydroxychloroquine – how does plaquenil work prednisone

Some truly interesting details you have written.Aided me a lot, justwhat I was searching for :D.Here is my blog Rapid Fire Diet

Really appreciate you sharing this article post.Much thanks again. Will read on…

Hello There. I found your blog the usage of msn. This is a very well written article.

I will be sure to bookmark it and return to learn more of your useful information.

Thank you for the post. I’ll definitely comeback.

Hey there just wanted to give you a quick heads up and let you know a few of the pictures aren’t loading properly. I’m not sure why but I think its a linking issue. I’ve tried it in two different internet browsers and both show the same results.

write my essay for me essay writer online

Thanks again for the blog post.Really looking forward to read more. Awesome.

Really informative article.Thanks Again. Cool.

Muchos Gracias for your blog article. Awesome.

Really appreciate you sharing this blog.Thanks Again. Awesome.

Great article.Much thanks again. Really Cool.

This is nicely expressed. ! thesis paper help me essays

This is one awesome blog article. Much obliged.

Say, you got a nice post. Awesome.

I wanted to thank you for this good read!! I definitely loved every bit of it. I have you book-marked to look at new things you postÖ

I loved your article.Really thank you! Fantastic.

You’re so awesome! I do not believe I’ve truly read through

a single thing like this before. So wonderful to discover somebody with some

unique thoughts on this subject. Seriously..

thanks for starting this up. This site is something that

is needed on the internet, someone with a bit of originality!

This is very interesting, You are a very skilled

blogger. I have joined your rss feed and look forward to seeking more of your excellent

post. Also, I have shared your website in my social networks!

After I initially commented I seem to have clicked on the -Notify me when new comments are added- checkbox and from now on every time a comment is added I recieve 4

emails with the same comment. Perhaps there is an easy method you are able to remove

me from that service? Thanks a lot!

Say, you got a nice article post.Much thanks again. Cool.

I’ve been exploring for a little bit for any high quality articles or blog

posts on this kind of space . Exploring in Yahoo I ultimately stumbled upon this site.

Reading this info So i am happy to show that I have a very just right uncanny feeling I discovered

exactly what I needed. I most indisputably will make certain to don?t omit this website and give it a look

regularly.

I am so grateful for your article.Really looking forward to read more. Much obliged.

I was suggested this blog by my cousin. I’m not sure whether this post is written by him as nobody else know such detailed about my problem. You are incredible! Thanks!

I am not sure where you’re getting your information, but good topic.I needs to spend some time learning more or understandingmore. Thanks for magnificent info I was looking for thisinformation for my mission.

Awesome blog article.Thanks Again.

I am not absolutely sure where you’re receiving your info, but excellent subject. I wants to invest a while Mastering far more or comprehension extra. Many thanks for exceptional info I was looking for this info for my mission

2 Inch/58mm Seriesinfant jordans sneakersシャネルバッグスーパーコピー通販店

Thanks for sharing, this is a fantastic blog post.Thanks Again. Really Great.

It’s really a cool and useful piece of information. I am happy that you simply shared this helpful info with us. Please stay us up to date like this. Thank you for sharing.

carrington court apartments oakstone apartments vista del lago apartments

I’m not sure exactly why but this blog is loading very slow for me. Is anyone else having this issue or is it a issue on my end? I’ll check back later and see if the problem still exists.

I gget pleasure from, leaqd to I discovered just what Iwas having a look for. You have endfed my 4 day lengthy hunt!God Bless you man. Have a nice day. Bye

I blog frequently and I seriously thank you for your information. The article has truly peaked my interest.I am going to bookmark your blog and keep checking for new detailsabout once per week. I opted in for your Feed too.

Hey There. I found your blog using msn. This isa really well written article. I will make sure tobookmark it and return to read more of your useful information. Thanksfor the post. I will certainly return.

I wanted to thank you for this wonderful read!!I absolutely loved every bit of it. I have got you book-marked to check out new stuff you post…Have a look at my blog … normal testosterone

I loved your article post.Really looking forward to read more. Awesome.

Appreciate you sharing, great blog post.Really thank you! Great.

A round of applause for your article.Much thanks again. Keep writing.

I truly appreciate this post.Really looking forward to read more. Will read on…

Really enjoyed this blog post.Much thanks again. Cool.

Im thankful for the article post.

ivermectin for demodex ivermectin injection for rabbits

Definitely believe that which you said. Your favorite

reason appeared to be on the internet the simplest thing to

be aware of. I say to you, I definitely get irked while people consider worries that they plainly do not know about.

You managed to hit the nail upon the top and defined

out the whole thing without having side-effects , people could take

a signal. Will likely be back to get more. Thanks

Tadalis SX canadian pharcharmy online fda approved

dairy land insurance usaa car insurance quotes general car insurance quotes

I loved your post.Much thanks again. Keep writing.

Great, thanks for sharing this post.Much thanks again. Awesome.

I blog often and I seriously thank you for your content. The article has really peaked my interest. I will book mark your blog and keep checking for new details about once per week. I opted in for your Feed too.

Fantastic blog post.Really looking forward to read more. Will read on…

I really like and appreciate your blog post.Really thank you! Much obliged.

It’s truly very complex in this active life to listen news on TV, so I just use internet for thatpurpose, and get the most up-to-date information.

Very informative article.Thanks Again. Much obliged.

Thank you for your article post.Much thanks again.

Very great post. I simply stumbled upon yourblog and wished to say that I’ve really enjoyed browsing your blogposts. In any case I will be subscribing to your rss feed and I am hoping you write again very soon!

Hi there! I could have sworn Iíve been to this blog before but after browsing through some of the posts I realized itís new to me. Regardless, Iím definitely pleased I came across it and Iíll be book-marking it and checking back regularly!

Awesome blog.Really thank you! Awesome.

I really liked your blog. Really Cool.

Very good article post.Really looking forward to read more. Keep writing.

Thanks for sharing, this is a fantastic post.Thanks Again. Cool.

I never thought about it that way, but it makes sense!Download PY Proxy Manager to easily generate and use S5 proxies or rotating residential proxies on your Windows device.

Thanks so much for the article post.Much thanks again. Fantastic.

I never thought about it that way, but it makes sense!,Docker代理是什么?

trust pharmacy best rogue online pharmacy – legal online pharmacy

Im grateful for the article.Much thanks again. Keep writing.

I appreciate you sharing this post.Really thank you! Will read on…

I cannot thank you enough for the post.Thanks Again. Great.

I am really inspired with your writing skills and also with the structure for your weblog. Is this a paid subject or did you customize it your self? Either way stay up the nice high quality writing, it is rare to look a nice blog like this one these days!

Awesome post.Thanks Again. Will read on…

I cannot thank you enough for the article post.Thanks Again.

Im grateful for the blog article.Thanks Again. Awesome.

Fantastic article post.Much thanks again. Great.

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7037

I never thought about it that way, but it makes sense!Static ISP Proxies perfectly combine the best features of datacenter proxies and residential proxies, with 99.9% uptime.

I am so grateful for your article post.Really thank you! Really Great.

Really informative article post.Thanks Again. Great.

Im grateful for the post. Great.

I never thought about it that way, but it makes sense!

Great, thanks for sharing this article. Keep writing.

I want to to thank you for this fantastic read!! I absolutely enjoyed every little bit of it. I have got you book marked to check out new stuff you postÖ

Muchos Gracias for your blog post. Awesome.

Really informative blog article.Really thank you! Keep writing.

essay writer online help with an essay how to write a essay argument essay

A big thank you for your blog article.Really looking forward to read more. Will read on…

order cipro: fucidin for salebiaxin tablets

Thanks-a-mundo for the blog article.Really thank you! Great.

Normally I do not read article on blogs, however I wish to say that this write-up very pressured me to take a look at and do so! Your writing style has been amazed me. Thanks, very nice article.

Fantastic article.Thanks Again. Really Cool.

Enjoyed every bit of your blog.Really thank you! Will read on…

Heya i am for the first time here. I found this board and I findIt really helpful & it helped me out much.I hope to present something back and help others like you helpedme.

Im thankful for the blog post.Really thank you! Keep writing.

Thanks again for the blog article. Really Great.

Thank you ever so for you blog article.Thanks Again. Fantastic.

Im obliged for the blog post.Much thanks again. Want more.

I don’t even know how I ended up here, but I thought thispost was great. I don’t know who you are but definitely you’re going to a famous blogger if you are not already😉 Cheers!

clomid without doctor supervision hoalt Boppy

I appreciate you sharing this blog article.Thanks Again. Keep writing.

Good response in return of this difficulty with solid arguments and explaining all concerning that.

Thank you for your very good information and feedback from you. car dealers san joserap instrumentals old school

This is my first time go to see at here and i am truly pleassant to read all at one place.

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7122

You’re consequently amazing. Oh my Jesus. Jesus bless you.

Heya! I just wanted to ask if you ever have any issues with hackers?My last blog (wordpress) was hacked and I ended up losing months of hard work due to no back up.Do you have any methods to prevent hackers?

I value the blog article.Really thank you! Really Great.

Really informative article.Really thank you! Cool.

Truly when someone doesn’t be aware of afterward its up to other people that they will assist, so here it takes place.

I never thought about it that way, but it makes sense!Static ISP Proxies perfectly combine the best features of datacenter proxies and residential proxies, with 99.9% uptime.

Usually I don’t read post on blogs, but I would like to say that this write-up very forced me to try and do it! Your writing style has been surprised me. Thanks, very nice post.

Im obliged for the blog.Much thanks again. Fantastic.

Im thankful for the post.Really thank you! Awesome.

Really enjoyed this blog.Thanks Again. Awesome.

Good day! Would you mind if I share your blog with my zynga group? There’s a lot of folks that I think would really appreciate your content. Please let me know. Many thanks

Very good https://lc.cx/xjXBQT

I cannot thank you enough for the article post.Much thanks again. Will read on…

Hi, I check your blogs regularly. Your humoristic style is witty, keep doing what you’re doing!

In the course of most common. sildenafil discount Trawlo iqyfqt

Thanks for the article. Will read on…

https://mazda-demio.ru/forums/index.php?autocom=gallery&req=si&img=6627

Major thankies for the blog.Really looking forward to read more.

wow, awesome post.Really looking forward to read more. Much obliged.

wow, awesome post.Really looking forward to read more.

I cannot thank you enough for the post. Great.

Ꮐood way of describing, and pleasant paragraph to get information on the topic of my presentation topic, which i am going to present in school.my blog – def leppard T shirts vintage

I truly appreciate this blog post.Really looking forward to read more. Cool.

I really liked your article.Really thank you! Will read on…

We are looking for some people that are interested in from working their home on a full-time basis. If you want to earn $500 a day, and you don’t mind developing some short opinions up, this is the perfect opportunity for you!

We are looking for some people that might be interested in from working their home on a full-time basis. If you want to earn $200 a day, and you don’t mind creating some short opinions up, this is the perfect opportunity for you!

I really liked your blog article.Thanks Again. Cool.

Great post. Fantastic.

https://hrv-club.ru/forums/index.php?autocom=gallery&req=si&img=7141

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6877

Major thankies for the blog. Awesome.

A round of applause for your blog post.Thanks Again. Really Cool.

IWSB mimicked tv baseball coverage by displaying the batter from amodified “center field” camera, the baserunners in cornerinsets and defensive plays from a camera behind the batter.

Thanks so much for the post. Cool.

I really like and appreciate your post.Thanks Again.

At this moment I am ready to do my breakfast, afterward having my breakfast coming again to read further news.

I really liked your post. Really Great.

I value the article post.Much thanks again. Keep writing.

Say, you got a nice blog.

http://terios2.ru/forums/index.php?autocom=gallery&req=si&img=4684

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6768

This is one awesome article.Really looking forward to read more. Will read on…

I really liked your blog post.Really looking forward to read more. Awesome.

I do consider all the concepts you have presented for your post. They’re very convincing and will definitely work. Still, the posts are too brief for starters. May just you please prolong them a bit from next time? Thanks for the post.

I think this is a real great post.Really looking forward to read more. Really Cool.

There is certainly a great deal to know about this subject. I like all of the points you’ve made.

This actually addressed my trouble, thanks!

What a material of un-ambiguity and preserveness ofvaluable know-how concerning unpredicted emotions.

What’s up, the whole thing is going nicely here and ofcourse every one is sharing facts, that’s truly good, keep up writing.

I like the helpful information you provide in your articles. I’ll bookmark your blog and check again here frequently. I am quite sure I’ll learn a lot of new stuff right here! Good luck for the next!

aserblog.com with ivermectin ivermectin tablets ivermectin for sale uk

https://mazda-demio.ru/forums/index.php?autocom=gallery&req=si&img=6470

http://terios2.ru/forums/index.php?autocom=gallery&req=si&img=4703

Thanks for finally writing about > Dispersan a 84 personas que realizaban actividades no esenciales en Acapulco – Mar de Noticias Guerrero

Excellent stuff. With thanks!why college essay pay people to write essays help writing dissertation

Thank you ever so for you post.Much thanks again. Awesome.

Beneficial stuff. Appreciate it.writing a persuasive essay powerpoint write papers essay writing service review

Thanks – Enjoyed this update, is there any way I can receive an email sent to me when there is a new article?

Hi! I could have sworn Iíve been to this blog before but after browsing through many of the posts I realized itís new to me. Anyhow, Iím certainly pleased I stumbled upon it and Iíll be bookmarking it and checking back frequently!

If you want to obtain much from this post then you have to apply these methods to your won blog.

I truly appreciate this blog.Really looking forward to read more. Great.

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7123

To increase accuracy as a kicker, learn the proper way to kick the ball. Emilee Ferdy Aube

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7124

I like the valuable information you provide in your articles. I’ll bookmark your blog and check again here frequently. I am quite sure I will learn a lot of new stuff right here! Best of luck for the next!

https://mazda-demio.ru/forums/index.php?autocom=gallery&req=si&img=6437

When someone writes an post he/she retains the image of auser in his/her mind that how a user can be aware of it.So that’s why this paragraph is outstdanding. Thanks!

Oh my goodness! Awesome article dude! Thank you, HoweverI am encountering problems with your RSS. I don’t know why I cannot join it.Is there anybody else having the same RSS problems? Anyone that knows the answer can you kindly respond?Thanks!!

Hello.This post was really fascinating, particularly because I was investigating for thoughts on this topic last Monday.

My brother suggested I might like this blog. He was entirely right. This post truly made my day. You cann’t imagine just how much time I had spent for this information! Thanks!

I can’t remember the last time I enjoyed an article as much as this one. You have gone beyond my expectations on this topic and I agree with your points. You’ve done well with this.Danny Willis

Financial institution of America supplies a couple of various rates tiers.Review my blog post: Ing bank Reviews australia

modafinil provigil provigil over the counter order modafinil

soma therapy ed: ed therapy – male erectile dysfunction

พนันบอลอย่างไรให้ได้เงิน แทงบอลชนะอย่างไรผิดฉ้อโกง UFABET จ่ายจริงจ่ายไม่ยั้งระบบเข้าใจง่าย แค่เพียงคลิกสมัครก็ทำเงินได้ง่ายๆกับคาสิโนออนไลน์ สบายสุดๆชีวิตชิวๆชีวิตคลูๆทำเงิน สร้างกำไรสบายๆต้องที่ UFABET

I read this paragraph completely about the comparison ofnewest and previous technologies, it’s remarkable article.

pay for paper writing – need a paper written writing assignments

I wish I had a dime for every bad article I’ve read lately. I also wish other writers had your talent and style. Thank you.slot deposit dana

I really liked your blog article.Really thank you! Awesome.

Thanks a lot for the article post.Really thank you! Keep writing.

Very neat blog article.Much thanks again. Keep writing.

Really informative blog article. Really Great.

Thanks-a-mundo for the blog.Really looking forward to read more. Fantastic.

Has anyone ever tried Market Freeze E-Juice Eliquid?

tadalafil troche tadalafil peptide tadalafil research chemical

great issues altogether, you simply received a new reader. What might you recommend about your submit that you just made some days in the past? Any positive?

This is one awesome article post. Really Cool.

Thank you. I appreciate it.descriptive essay writing essay typer copywriting service

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6875

http://terios2.ru/forums/index.php?autocom=gallery&req=si&img=4824

I appreciate you sharing this article. Awesome.

Terrific posts. Many thanks. homeworkcourseworkhelp.com personal statement college essay

http://terios2.ru/forums/index.php?autocom=gallery&req=si&img=4863

http://terios2.ru/forums/index.php?autocom=gallery&req=si&img=4457

They are very convincing and will certainly work.

Enjoyed every bit of your blog article.Really looking forward to read more. Cool.

Oh my goodness! a remarkable post man. Thank you However I am experiencing problem with ur rss. Don?t know why Incapable to subscribe to it. Is there anybody getting the same rss problem? Anybody that knows kindly respond. Thnkx

purchase ivermectin – ivermectine online stromectol sales

hi!,I love your writing very so much! percentage we keep up a correspondence extra about your post on AOL? I require an expert on this area to resolve my problem. Maybe that is you! Having a look forward to peer you.

I think one of your adverts caused my browser to resize, you may well want to put that on your blacklist.

Hey, thanks for the blog article. Really Great.

A round of applause for your post.Much thanks again. Much obliged.

valtrex daily use: valtrex for sale – order valtrex online usahow much is valtrex in canada

Looking forward to reading more. Great post.Really thank you! Much obliged.

Thank you for the good writeup. It if truth be told was once a enjoyment account it. Glance advanced to far introduced agreeable from you! By the way, how could we communicate?

wow, awesome blog article.Really thank you! Will read on…

สำหรับ..คนยังไม่เคยแตกทักไปเลยเล่นแล้วปังปังฝาก-ถอน รวดเร็วออนไลน์ 24 ชม.อิอิ

Regards, Terrific stuff!how to write an cause and effect essay essay revision help online homework help writing

Modifying your strategy to the different types is easy. How many of the leading poker players about the globe frequent there? It’s also nice to have a pretty big chip stack compared to the other players in situation you do get known as.

Very good article.Really thank you! Really Great.

Good information. Lucky me I recently found your blog by accident (stumbleupon). I’ve bookmarked it for later!

Hi my loved one! I want to say that this post is amazing, nice written and come with almost all important infos.I’d like to see more posts like this .Feel free to surf to my blog :: digital marketing firm based in Austin

Thank you for some other excellent post. Where else could anybodyget that kind of info in such a perfect way of writing?I have a presentation subsequent week, and I’m on the lookfor such info.

I am so grateful for your blog article.Really thank you!

Thank you a lot for sharing this with all people you actually recognise what you are speaking about!

After I initially commented I clicked the -Notify me when new comments are added- checkbox and now every time a comment is added I get 4 emails with the identical comment. Is there any approach you may remove me from that service? Thanks!

legimate owner get to use enough free PSN card to giveaway.

I appreciate you sharing this blog.Really thank you! Cool.

Muchos Gracias for your article. Want more.

Thanks for the post, can I set it up so I receive an alert email whenever you publish a fresh update?

A round of applause for your blog.Thanks Again. Awesome.

I like the valuable information you provide in your articles.I will bookmark your blog and check again here regularly.I’m quite certain I’ll learn lots of new stuffright here! Good luck for the next!

Enjoyed every bit of your blog.Really looking forward to read more. Fantastic.

Thank you ever so for you blog.Thanks Again. Really Cool.

Hello every one, here every person is sharing these know-how, thus it’s fastidious to read this blog, and I used to go to see this blog daily.

Very good post.Really looking forward to read more. Keep writing.

I cannot thank you enough for the article.Much thanks again. Will read on…

Thanks for the post.Really thank you! Will read on…

I appreciate you sharing this post.Really thank you! Fantastic.

http://wish-club.ru/forums/index.php?autocom=gallery&req=si&img=5289

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4868

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4868

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7098

http://wish-club.ru/forums/index.php?autocom=gallery&req=si&img=5293

http://wish-club.ru/forums/index.php?autocom=gallery&req=si&img=5295

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4867

http://wish-club.ru/forums/index.php?autocom=gallery&req=si&img=5291

http://wish-club.ru/forums/index.php?autocom=gallery&req=si&img=5296

wow, awesome post.Much thanks again. Will read on…

Absolutely pent articles , regards for entropy.

Sweet blog! I found it while surfing aroundon Yahoo News. Do you have any tips on how to get listed in Yahoo News?I’ve been trying for a while but I never seem to get there!Thanks

Thanks for sharing, this is a fantastic blog article.Thanks Again. Great.

Really informative blog article.Much thanks again. Really Cool.

I was suggested this blog by my cousin. I am not sure whether this post is written by him as nobodyelse know such detailed about my trouble. You are wonderful!Thanks!

Very neat blog article.Thanks Again. Keep writing.

Say, you got a nice blog.Really thank you! Will read on…

I have read so many posts concerning the blogger lovers except this piece of writing is truly a pleasant paragraph, keep it up.

Thanks for the blog post.Really looking forward to read more. Fantastic.

Алина Гросу – Вова скачать и слушать песню https://shorturl.fm/y5tsE

Макс Корж – 2 типа людей скачать песню и слушать бесплатно https://shorturl.fm/mOa8n

Иосиф Кобзон – Бирюсинка скачать и слушать песню бесплатно https://shorturl.fm/qWJtp

Clava Crash – Самоволочка ( 2004 ) скачать и слушать mp3 https://shorturl.fm/sJIM9

Баста & Zivert – Неболей (Denis First Remix) скачать и слушать песню https://shorturl.fm/YOvyp

Сябры – Глухариная заря скачать и слушать онлайн https://shorturl.fm/5rNR8

Say, you got a nice post. Great.

Чи-ли – Я желаю тебе скачать mp3 и слушать бесплатно https://shorturl.fm/FIXqq

Валерий и Вадим Мищуки – Скоро будем дома скачать и слушать песню https://shorturl.fm/hX6kD

At this time it appears like WordPress is the preferred bloggingplatform out there right now. (from what I’ve read) Is that what youare using on your blog?

Really appreciate you sharing this article post.Much thanks again. Fantastic.

over the counter ed treatment: ed pills online pharmacy hims ed pills

Im obliged for the blog.Really thank you! Really Great.

This is one awesome blog article. Great.

Usually I do not learn article on blogs, but I wish to say that this write-up very forced me to check out and do it! Your writing style has been surprised me. Thanks, very nice post.

Enjoyed every bit of your blog article.Much thanks again. Keep writing.

Hello, yup this piece of writing is genuinely pleasantand I have learned lot of things from it regarding blogging.thanks.

Thanks so much for the post.Thanks Again.

I really like and appreciate your blog. Will read on…

Thanks a lot for the article.Thanks Again.

A round of applause for your blog.Thanks Again. Keep writing.

These are really great ideas in on the topic of blogging. You havetouched some fastidious things here. Any way keep up wrinting.

Muchos Gracias for your blog.Really looking forward to read more. Will read on…

I like reading through a post that can make men and women think. Also, many thanks for permitting me to comment.

ed pills that work – erectile dysfunction medicines pills for ed

Very neat post.Really thank you! Keep writing.

Yeah bookmaking this wasn’t a bad determination great post!마사지

Im grateful for the blog.Much thanks again. Keep writing.

Really enjoyed this post.Really thank you!

Im obliged for the blog post.Really looking forward to read more. Keep writing.

Enjoyed every bit of your article post.Really looking forward to read more. Fantastic.

I cannot thank you enough for the article post.Really looking forward to read more. Fantastic.

I think this is a real great blog post.Really looking forward to read more. Much obliged.

Awesome article.Thanks Again. Keep writing.

Very neat article. Much obliged.

I appreciate you sharing this article post.Really thank you! Will read on…

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4990

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4858

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4858

http://passo.su/forums/index.php?autocom=gallery&req=si&img=4269

http://terios2.ru/forums/index.php?autocom=gallery&req=si&img=4854

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7287

http://terios2.ru/forums/index.php?autocom=gallery&req=si&img=4658

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6764

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4809

http://terios2.ru/forums/index.php?autocom=gallery&req=si&img=4603

Hey, thanks for the blog.Really thank you! Cool.

I loved your post.Really thank you! Cool.

Thanks again for the post.Thanks Again. Keep writing.

Thank you for your post. Great.

I am so grateful for your blog.Thanks Again. Keep writing.

Appreciate you sharing, great article post.Thanks Again. Much obliged.

Great blog.Really thank you! Cool.

Roman Donskoy – Глубина скачать mp3 и слушать бесплатно https://shorturl.fm/0J9EU

Владимир Ковальчук – Бродяга скачать и слушать песню https://shorturl.fm/fCzKG

D-Band – Ангел В Плаще скачать mp3 и слушать онлайн бесплатно https://shorturl.fm/p1ViC

Наталия Гулькина – Я Просто Женщина скачать песню и слушать онлайн https://shorturl.fm/nHLOY

Inice – Сникерсы скачать и слушать mp3 https://shorturl.fm/R5l9U

Ellaya – Свет Сквозь Шрам скачать mp3 и слушать онлайн https://shorturl.fm/QemAt

Aktash – Если Я Уйду скачать песню в mp3 и слушать онлайн https://shorturl.fm/0ghaa

Hisma – Подойди Поближе скачать и слушать онлайн https://shorturl.fm/KHnJ6

ZAPOLYA – Вечеринок больше нет скачать песню и слушать бесплатно https://shorturl.fm/EchAT

Сюзанна – Святая вода скачать песню и слушать бесплатно https://shorturl.fm/gC3Mz

Thank you for your post. Much obliged.

I am so grateful for your blog.Really looking forward to read more. Want more.

Really appreciate you sharing this blog post.Much thanks again. Much obliged.

Really appreciate you sharing this article.Really thank you! Keep writing.

wow, awesome post.Thanks Again. Fantastic.

Hi, just wanted to mention, I enjoyed this blog post. It was helpful. Keep on posting!

I really enjoy the blog article.Thanks Again. Much obliged.

Hello friends, how is everything, and what you wish for to say about this article, in my viewits truly awesome for me.

I’d must test with you here. Which isn’t one thing I normally do! I enjoy studying a submit that can make individuals think. Also, thanks for permitting me to comment!

I enjoy what you guys are up too. Such clever work and reporting!Keep up the very good works guys I’ve included you guys to my personal blogroll.

Wow, great blog post.Really thank you! Really Great.

Article writing is also a excitement, if you knowthen you can write or else it is complicated to write.

Hello there! This blog post couldn’t be written much better!Looking at this post reminds me of my previous roommate!He continually kept talking about this. I’ll send this articleto him. Pretty sure he’ll have a very good read. Thank you forsharing!

Wow, great article post.Much thanks again.

Good day! Do you use Twitter? I’d like to followyou if that would be okay. I’m undoubtedly enjoying your blogand look forward to new updates.

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7275

http://passo.su/forums/index.php?autocom=gallery&req=si&img=4259

http://wish-club.ru/forums/index.php?autocom=gallery&req=si&img=5280

https://hrv-club.ru/forums/index.php?autocom=gallery&req=si&img=6939

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6806

https://mazda-demio.ru/forums/index.php?autocom=gallery&req=si&img=6465

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4956

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6649

http://toyota-porte.ru/forums/index.php?autocom=gallery&req=si&img=3281

http://passo.su/forums/index.php?autocom=gallery&req=si&img=4263

Your style is so unique compared to other folks I have read stuff from. Thanks for posting when you have the opportunity, Guess I will just bookmark this blog.

Major thankies for the article post.Much thanks again. Awesome.

Really appreciate you sharing this blog article.Really thank you! Will read on…

managing contraceptive pill patients 15th ed by richard p dickey – erectile dysfunction medication insurance coverage bam ed pills

ivermectin uk stromectol tablets – ivermectin generic name

Looking forward to reading more. Great article post. Awesome.

Bokova – Многоточие скачать mp3 и слушать онлайн https://shorturl.fm/BuZlB

Инфинити – Обманщик скачать бесплатно mp3 и слушать онлайн https://shorturl.fm/91mPP

Гуф, Мари Краймбрери – 31 февраля скачать бесплатно и слушать онлайн https://shorturl.fm/xRDEj

TSAB – Подруга скачать песню на телефон и слушать бесплатно https://shorturl.fm/PRBCu

Дуэт Алмас – Disco скачать песню на телефон и слушать бесплатно https://shorturl.fm/KOUoi

ВИА «Песняры» – Дорогой Длинною скачать mp3 и слушать онлайн https://shorturl.fm/gadZz

ПоэтОМУ feat. Swipe – Заряжай Магнитофон скачать бесплатно mp3 и слушать онлайн https://shorturl.fm/K8PXk

Lina Lee feat. Матвей Балов – Вдох-выдох скачать и слушать песню бесплатно https://shorturl.fm/zSKMP

Владимир Ковальчук – Бродяга скачать mp3 и слушать бесплатно https://shorturl.fm/J7SgZ

Major thanks for the blog.Really looking forward to read more.

When someone writes an piece of writing he/she keeps the image of a user in his/her brain that how a user can understand it.So that’s why this post is great. Thanks!

There is definately a great deal to learn about this topic. I love all the points you made.

ed tablets rx online india – new treatments for ed

The information talked about inside the article are several of the ideal offered

Thank you for your article post. Cool.

Thanks for the blog.Really thank you! Really Great.

Everyone loves what you guys tend to be up too. This kind of clever work and reporting! Keep up the terrific works guys I’ve incorporated you guys to our blogroll.

Appreciate you sharing, great blog post.Much thanks again. Great.

Thank you ever so for you blog post.Thanks Again. Want more.

A motivating discussion is worth comment. I think that you should publish more about this subject, it might not be a taboo matter but generally folks don’t talk about these issues. To the next! Kind regards!!

Thanks for the article post.Really thank you! Fantastic.

I really like and appreciate your blog article.Really thank you! Really Cool.

wow, awesome blog.Thanks Again.

Really appreciate you sharing this blog article. Keep writing.

Moi aussi je suis fan de Sonic! (Ah.. c’etait pas la question..?)

order amoxicillin online uk bactrim ds antibiotic – generic amoxicillin

Hey There. I discovered your blog the use of msn. That is a really well written article. I will be sure to bookmark it and come back to read more of your helpful information. Thank you for the post. I will certainly comeback.

This was a super good article. You now have a big fan. Thank you for writing it.

I’m now not sure where you’re getting your info, but great topic.I needs to spend some time learning more or workingout more. Thanks for wonderful information I used to be searching for thisinfo for my mission.

Really enjoyed this blog.Really thank you! Fantastic.

Cool article it’s really. Friend on mine has long been awaiting just for this content.look here

Thanks so much for the article post. Cool.

Hello, its fastidious post regarding media print, we all know media is a fantastic source of facts.

Very good blog article.Much thanks again. Really Great.

Hi, I check your blogs like every week. Your humoristic style is awesome, keep it up!

Thanks a lot for the blog post.Thanks Again.

Thanks so much for the blog.Really looking forward to read more. Want more.

Hi there mates, fastidious piece of writing and good arguments commented at this place, I am actually enjoying by these.

what is the best canadian online pharmacy canadian pharmacy antibiotics

A big thank you for your blog post.Really looking forward to read more. Really Cool.

Very good blog.Really thank you!

Im thankful for the article post.Really thank you! Really Cool.

Oh my benefits! an outstanding short article dude. Thanks However I am experiencing problem with ur rss. Don?t recognize why Incapable to register for it. Exists anybody obtaining identical rss problem? Anybody that recognizes kindly respond. Thnkx

Paragraph writing is also a fun, if you be familiar withafterward you can write or else it is complex to write.

stromectol tablets for humans ivermectin wormers for horses

Great post about this. I’m surprised to see someone so educated in the matter. I am sure my visitors will find that very useful.

the canadian pharmacy – canadian pharmacy ltd legit canadian pharmacy online

An interesting discussion is worth comment. I do believe that you ought to publish more about this issue, it may not be a taboo subject but generally people don’t discuss these topics. To the next! Kind regards!!

Enjoyed every bit of your article post.Thanks Again. Really Great.

Absolutely indited content material, appreciate it for selective information. «He who establishes his argument by noise and command shows that his reason is weak.» by Michel de Montaigne.

Free Shipping Dutasteride Internet Shipped Ups

Thanks so much for the article.Really thank you! Great.

You could certainly see your expertise in the article you write.The sector hopes for even more passionate writers suchas you who aren’t afraid to mention how they believe.Always go after your heart.

Really informative post.Much thanks again. Awesome.

Thanks again for the article.Really looking forward to read more. Fantastic.

Fantastic article.Much thanks again.

Thank you for your blog post. Really Cool.

Людмила Зыкина – Рязанские мадонны скачать песню и слушать онлайн

https://allmp3.pro/3172-ljudmila-zykina-rjazanskie-madonny.html

Пицца – Сахар скачать песню и слушать онлайн

https://allmp3.pro/3248-picca-sahar.html

Aleks Ataman & Finik.Finya – Ойойой (Ты Говорила) скачать песню и слушать онлайн

https://allmp3.pro/3141-aleks-ataman-finikfinya-ojojoj-ty-govorila.html

Jowell & Randy – Tуxicos скачать песню и слушать онлайн

https://allmp3.pro/2877-jowell-randy-tuxicos.html

Пацаны – Плачешь скачать песню и слушать онлайн

https://allmp3.pro/2764-pacany-plachesh.html

Grishina и «Storm DJs» – До кипения скачать песню и слушать онлайн

https://allmp3.pro/2836-grishina-i-storm-djs-do-kipenija.html

Andery Toronto feat. Диман Брюханов – Вороной скачать песню и слушать онлайн

https://allmp3.pro/2857-andery-toronto-feat-diman-brjuhanov-voronoj.html

ALMARY – В твоих глазах скачать песню и слушать онлайн

https://allmp3.pro/2496-almary-v-tvoih-glazah.html

Beeswax & Olesya – Это невозможно скачать песню и слушать онлайн

https://allmp3.pro/2452-beeswax-olesya-jeto-nevozmozhno.html

Yanix feat. Дора – Вне Зоны скачать песню и слушать онлайн

https://allmp3.pro/2939-yanix-feat-dora-vne-zony.html

Aw, this was an exceptionally good post. Taking the time and actual effort to generate a good article… but what can I say… I hesitate a lot and never manage to get nearly anything done.

I read this article fully concerning the resemblance of newest and earlier technologies, it’s amazing article.

Good information. Lucky me I ran across your blog by accident (stumbleupon). I’ve book-marked it for later!

Thanks a lot for the blog article.Much thanks again. Cool.

I appreciate you sharing this blog post.Really thank you! Awesome.

Aw, this was a really good post. Taking the time and actual effort to generate a very good articleÖ but what can I sayÖ I hesitate a lot and never manage to get anything done.

That is a really good tip particularly to those new to the blogosphere. Short but very precise infoÖ Many thanks for sharing this one. A must read post!

I will right away seize your rss as I can not find your e-mail subscription link or e-newsletter service. Do you have any? Please permit me understand in order that I could subscribe. Thanks.

I am so grateful for your post.Really looking forward to read more. Awesome.

Hello, I enjoy reading all of your article. I like to write a little comment to support you.Here is my blog :: ketogenic diet

I really liked your blog post. Great.

Looking forward to reading more. Great article. Fantastic.

Hello are using WordPress for your blog platform? I’m new to the blog world but I’m trying to get started and set up my own. Do you require any html coding expertise to make your own blog? Any help would be really appreciated!

Really enjoyed this post.Really thank you! Will read on…

Thanks-a-mundo for the blog article.Really thank you! Will read on…

Thanks for sharing, this is a fantastic blog.Really looking forward to read more. Much obliged.

Major thanks for the blog.Thanks Again. Great.

Pretty! This was an extremely wonderful post. Many thanks for providing these details.

Very good blog article.Really thank you!

Thanks a lot for the post.Really looking forward to read more. Fantastic.

Muchos Gracias for your blog post.Really looking forward to read more. Awesome.

I really like and appreciate your blog.Really thank you! Keep writing.

I don’t even know how I ended up here, but I thought this post was good.I don’t know who you are but certainly you’re going to a famous blogger if you are not already 😉 Cheers!

apartments in princeton nj rentberry scam ico 30m$ raised apartments watertown ny

I truly appreciate this blog. Really Cool.

Hello, everything is going nicely here and ofcourse every one is sharing facts, that’s actually good,keep up writing.

Touche. Outstanding arguments. Keep up the amazing work.

Aw, this was a really good post. Finding the time and actual effort to generate a superb articleÖ but what can I sayÖ I procrastinate a whole lot and never seem to get anything done.

Helpful tips. Regards! Advair Diskus Instructions In Spanish

Awesome post.Really thank you! Much obliged.

where to get zithromax over the counter zithromax azithromycin zithromax tablets

Really informative post.Much thanks again. Want more.

Nice answers in return of this issue with solid argumentsand describing all regarding that.

I am not real fantastic with English but I get hold this very easy to interpret.

I love what you guys are usually up too. This type of clever work and coverage!Keep up the very good works guys I’ve incorporated you guys to my personal blogroll.

I truly appreciate this blog.Really thank you! Much obliged.

This is my first time visit at here and i am really impressed to read all at alone place.

Wonderful blog! I found it while searching on YahooNews. Do you have any tips on how to get listed in Yahoo News?I’ve been trying for a while but I never seem to get there!Appreciate it

Major thanks for the blog article.Really thank you! Awesome.

Enjoyed every bit of your post. Fantastic.

A round of applause for your blog article.Really looking forward to read more. Will read on…

ivermectin liquid for dogs what worms does ivermectin kill in dogs

My brother suggested I might like this blog. He used tobe entirely right. This post truly made my day. You can not imagine simply how so much timeI had spent for this info! Thank you!

I loved your blog.Thanks Again.

Very informative blog article.Really thank you! Great.

I loved your blog article.Thanks Again.

Thanks for the blog post.Thanks Again. Want more.

Im obliged for the article.Really looking forward to read more. Great.

Really informative article post.Really looking forward to read more. Really Cool.

Muchos Gracias for your blog. Awesome.

oral ivermectin for chickens ivermectin pyrantel generic

furosemide 80 what type of diuretic is furosemide how fast does lasix work

Major thankies for the article post.Thanks Again. Really Cool.

I’ll right away grab your rss feed as I can’t find your e-mail subscription link or e-newsletter service. Do you have any? Kindly let me know so that I could subscribe. Thanks.

I appreciate you sharing this blog post.Much thanks again. Really Great.

Very good post.Much thanks again. Really Great.

Thanks again for the article post. Really Cool.

Fantastic article post.Really looking forward to read more. Really Cool.

Thanks again for the blog post. Keep writing.

A round of applause for your article. Fantastic.

1 ivermectin dosage for dogs ivermectin for swine oral

Currently it looks like Drupal is the top blogging platform out there right now.(from what I’ve read) Is that what you’re usingon your blog?

I never thought about it that way, but it makes sense!Static ISP Proxies perfectly combine the best features of datacenter proxies and residential proxies, with 99.9% uptime.

Thank you for any other informative blog. The place else could I get that type of info written in such an ideal means? I’ve a project that I am just now working on, and I have been at the look out for such info.

campus walk apartments apartment styles lincoln court apartments

An interesting discussion is worth comment. There’s no doubt that that you ought to write more about this issue, it may not be a taboo subject but usually folks don’t speak about these issues. To the next! Kind regards!!

Greetings! Very useful advice in this particular article!It is the little changes that produce the biggest changes.Many thanks for sharing!

I?m not sure where you are getting your information, but good topic. I needs to spend some time learning much more or understanding more. Thanks for excellent information I was looking for this information for my mission.

Remarkable! Its genuinely remarkable post, I have got much clear idea about from this piece of writing.

always i used to read smaller content that also clear their motive, and that is also happening with this piece of writing which I am reading at this place.

I think this is a real great article post.Really thank you! Cool.

Howdy! This post couldnít be written any better! Going through this article reminds me of my previous roommate! He continually kept talking about this. I will send this post to him. Pretty sure he will have a very good read. Many thanks for sharing!

If you want to obtain much from this post then you have to apply such techniques to your won blog.

Aw, this was a really nice post. Finding the time and actual effortto make a very good article… but what can I say…I procrastinate a lot and never manage to get anythingdone.

Currently it seems like BlogEngine is the top blogging platform out there right now. (from what I’ve read) Is that what you’re using on your blog?

Wow, great article post. Keep writing.

Thank you for your article post.Much thanks again. Great.

Thanks so much for the article.Really looking forward to read more. Really Great.

that is the end of this article. Right here you

Hi there, just wanted to tell you, I liked this post.It was practical. Keep on posting!

Wow! This could be one particular of the most beneficial blogs We have ever arrive across on this subject. Basically Fantastic. I am also an expert in this topic so I can understand your effort.

Hello there! Do you know if they make any plugins to help with SEO?I’m trying to get my blog to rank for some targeted keywords but I’m not seeing very good gains.If you know of any please share. Thank you!

Greetings! Very useful advice within this article!It is the little changes that will make the largest changes.Thanks a lot for sharing!

Hello There. I found your blog using msn. This is a really well written article. I will be sure to bookmark it and return to read more of your useful info. Thanks for the post. I’ll definitely return.

That is a very good tip particularly to those new to the blogosphere. Simple but very precise info… Appreciate your sharing this one. A must read article!

A round of applause for your article post.Really looking forward to read more. Will read on…

Thanks for sharing your thoughts about software company.Regards

These are really great ideas in regarding blogging.You have touched some good factors here. Any way keep up wrinting.

fantastic post, very informative. I wonder why the other experts of this sector don’t notice this. You should continue your writing. I’m confident, you’ve a great readers’ base already!

Great, thanks for sharing this blog article. Awesome.

The work Morcos Key is doing is groundbreaking

Thanks for finally writing about > بالفيديو: بعدأن رفضتها الكثير من الشركات بعد زواجها، الشابة نادية بدأت عملها في مجال الديليفري!!!

proscar canadian pharmacy search canadian pharmacy

Enjoyed every bit of your article.Really thank you! Really Cool.

Great, thanks for sharing this article. Really Great.

Outstanding!!! I loved your blog! Keep them coming!

That’s great to hear Cathy — stick at it, success is only around the corner! 🙂

Hey there! I’ve been reading your blog for a long time now and finally got the courageto go ahead and give you a shout out from HumbleTexas! Just wanted to mention keep up thegood work!

I wished to compose you one particular extremely little remark to finally say thanks when far more over the

Hi there, everything is going nicely here and ofcourse everyone is sharing data, that’s genuinely excellent, keep upwriting.

azithromycin and ureaplasma urealyticum – azithromycin over the counter cvs free zithromax

I have read so many articles or reviews about the blogger lovers but this paragraph istruly a good post, keep it up.

It’s going to be end of mine day, however before ending Iam reading this enormous paragraph to increase my know-how.

Very informative blog post. Great.

Thank you for some other wonderful post. The placeelse may just anyone get that kind of information in such a perfect method of writing?I have a presentation next week, and I’m at the search for suchinformation.

I enjoy reading a post that can make men and women think. Also, thank you for permitting me to comment!